LEX-1000

Elevate your lens edging precision with the NIDEK LEX-1000.

Experience the future of lens edging with the NIDEK LEX-1000. Designed to meet the demands of modern eyewear and advanced lens technologies, this state-of-the-art edging system delivers unparalleled accuracy and efficiency.

Key Features:

- Customized Bevel Profiles: The LEX-1000’s innovative technology enables you to create bespoke bevel profiles for even the most challenging lenses, ensuring a perfect fit and flawless finish every time.

- Advanced Lens Processing: Independently process both the front and rear bevels to achieve optimal results for highly curved lenses, including progressive and high-index designs.

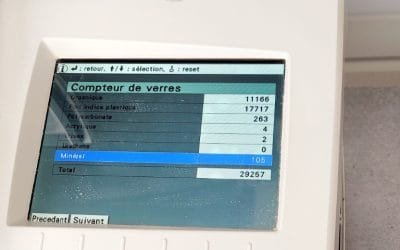

- Intuitive Interface: The color touchscreen interface provides easy navigation and control, allowing you to effortlessly adjust settings and monitor the edging process.

- Whisper-Quiet Operation: Enjoy a peaceful work environment with the LEX-1000’s quiet operation, minimizing distractions and enhancing productivity.

- Robust Construction: Built to last, the LEX-1000 is designed for demanding professional use, ensuring reliable performance and longevity.

- 3D Bevel Simulation: Visualize the final bevel profile before edging to confirm accuracy and make any necessary adjustments.

- Direct Lens Rotation: Maintain a stable cylindrical axis for precise and consistent results.

Benefits:

- Improved Customer Satisfaction: Deliver exceptional quality eyewear with a perfect fit, enhancing customer satisfaction and loyalty.

- Increased Efficiency: Streamline your edging process with the LEX-1000’s automation and advanced features, saving you time and effort.

- Versatility: Handle a wide range of lens materials and designs with ease, accommodating the latest trends in eyewear.

- Reduced Waste: Minimize lens breakage and rework with the LEX-1000’s precision and reliability.

I wanted to know if all the calibration tools as well as accessories were available for each piece of equipment

This list is purely informative and in no way reflects reality. Please check the presence of the accessories in the photos below. No claim will be accepted. For more information you can consult the website

Do the photos correspond to the reference above or are they generic?

The photographs illustrating the products are contractual pictures. Photos are taken for each machine: each picture and each video are REAL ones.

Are your machines perfectly functional? And calibrated ready to cut?

The best machines and only “one first owner” models before, are choosen for being renovated process. Then, they are fully refurbished by our qualified technicians, and calibrated here in Montluçon, middle France. The products sold by SARL Digital Screen System are Second Hand market, so we encourage our customers to make an educated decision, take responsibility, and to remember that it’s still pre-owned ones, aesthetically and mechanically.