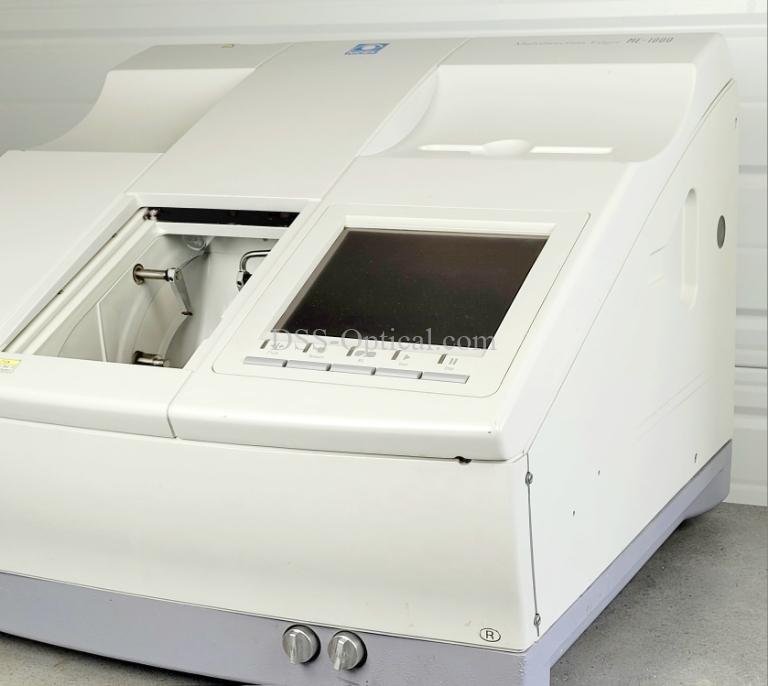

ME-1000

NIDEK ME-1000 Technical Description

The NIDEK ME-1000 is a state-of-the-art, fully automated lens edger designed to deliver precision and efficiency in lens finishing. This advanced machine offers a range of features that make it a preferred choice for opticians and laboratories worldwide:

- 3D Drilling Technology: The ME-1000 is renowned for its innovative 3D drilling technology, which enables precise and consistent drilling of lenses with various shapes and thicknesses.

- Patternless Edging: This feature allows for cylindrical axis edging with every cut, eliminating the need for pre-programmed patterns and enhancing flexibility.

- High-Precision Components: The ME-1000 is constructed with high-quality components, ensuring durability and long-lasting performance.

- User-Friendly Interface: The intuitive interface makes it easy to operate, even for less experienced users.

- Versatility: The machine can handle a wide range of lens materials and designs, making it suitable for various applications.

- Automation: The automated processes minimize manual intervention and reduce the risk of human error.

- Enhanced Efficiency: The ME-1000 significantly improves production efficiency by reducing cycle times and optimizing workflow.

Key Benefits:

- Improved Accuracy: The 3D drilling technology ensures precise and consistent results, leading to a higher quality of finished lenses.

- Increased Flexibility: The patternless edging feature allows for greater customization and adaptability to different lens designs.

- Reduced Labor Costs: Automation and efficiency gains contribute to significant cost savings.

- Enhanced Customer Satisfaction: The ability to produce high-quality lenses quickly and accurately leads to increased customer satisfaction.

Applications:

The NIDEK ME-1000 is widely used in optical laboratories and eye care facilities for:

- Eyeglass Lens Finishing: The machine is ideal for edging a variety of lenses, including single vision, bifocal, and progressive lenses.

- Sunglass Lens Finishing: It can also be used for finishing sunglass lenses with various tints and coatings.

- Safety Glasses: The ME-1000 is suitable for edging safety glasses with specific requirements.

NIDEK ME-1000, automatic lens edger, drill

I wanted to know if all the calibration tools as well as accessories were available for each piece of equipment

This list is purely informative and in no way reflects reality. Please check the presence of the accessories in the photos below. No claim will be accepted. For more information you can consult the website

Do the photos correspond to the reference above or are they generic?

The photographs illustrating the products are contractual pictures. Photos are taken for each machine: each picture and each video are REAL ones.

Are your machines perfectly functional? And calibrated ready to cut?

The best machines and only “one first owner” models before, are choosen for being renovated process. Then, they are fully refurbished by our qualified technicians, and calibrated here in Montluçon, middle France. The products sold by SARL Digital Screen System are Second Hand market, so we encourage our customers to make an educated decision, take responsibility, and to remember that it’s still pre-owned ones, aesthetically and mechanically.